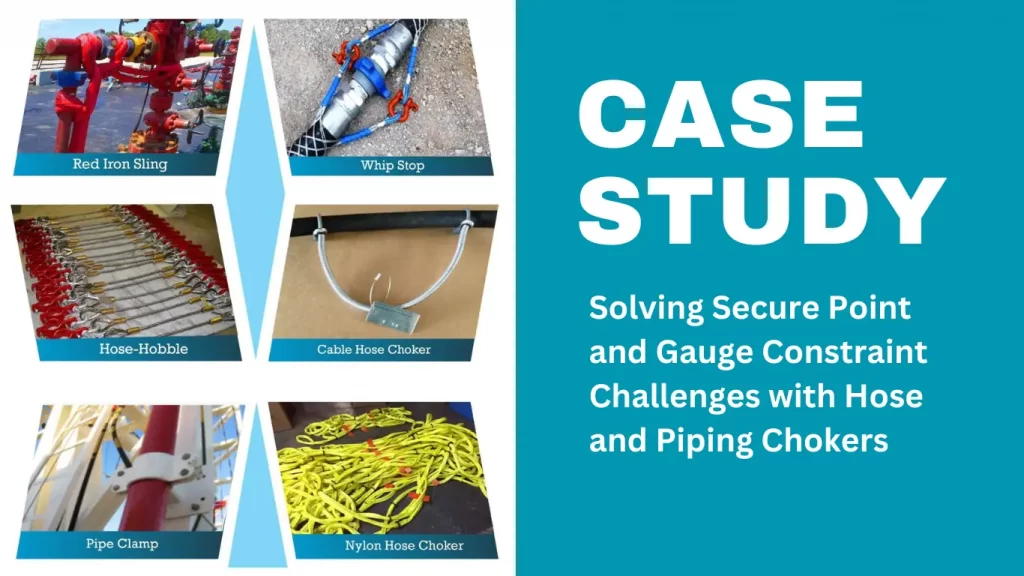

Solving Secure Point and Gauge Constraint Challenges with Hose and Piping Chokers: A Case Study

1. Introduction

Singapore-based company approached RAAH Group for solutions to address challenges related to secure points for loops of whip stops and gauge usage. The situation at hand required innovative solutions to ensure the safety and efficiency of their hose and piping systems. This case study outlines how RAAH Group‘s Hose and Piping Chokers proved to be a reliable and effective solution for their needs.

2. The Challenge

That company faced two significant challenges in their hose and piping systems:

2.1 Inadequate Secure Points for Whip Stops:

Existing systems lacked proper secure points for whip stops, causing concerns about the stability and reliability of the hoses and pipes. Many whip stops were only attached to the easiest point of the needle valve handle, which compromised the overall safety and durability of the system.

2.2 Incompatible Gauge Usage:

The second challenge involved the inability to use whip stops in conjunction with gauges. Gauges are crucial for monitoring pressure and other essential parameters in the system. However, their design posed compatibility issues with conventional whip stops, leading to potential hazards and the risk of damage to the gauges.

3. RAAH Group’s Solution

RAAH Group offered a comprehensive solution by introducing their innovative Hose and Piping Chokers. These specialized chokers are designed to address both challenges effectively:

3.1 Enhanced Secure Points:

The Hose and Piping Chokers offered by RAAH Group feature secure points that are specifically engineered to provide optimal attachment locations for whip stops. Unlike conventional setups that rely on the needle valve handle, these chokers enable secure attachment at multiple points along the hoses and pipes, ensuring a stable and safe setup.

3.2 Gauge Compatibility:

RAAH Group’s Hose and Piping Chokers are engineered to accommodate gauges seamlessly. With the incorporation of specially designed gauge attachment points, these chokers enable easy and secure mounting of gauges on the hoses and pipes without compromising their integrity.

4. Benefits and Results

By implementing RAAH Group’s Hose and Piping Chokers, that company experienced several benefits:

4.1 Improved Safety: The enhanced secure points significantly improved the safety of their hose and piping systems. The chokers provided stable anchor points for whip stops, minimizing the risk of sudden hose or pipe disconnections.

4.2 Gauge Monitoring: With the gauge compatibility feature, that company gained the ability to monitor pressure and other critical parameters in real-time. This allowed for timely responses to changes in the system, preventing potential issues and ensuring smooth operations.

4.3 Enhanced Durability: The chokers’ robust construction and reliable attachment points increased the durability of their hoses and pipes. This resulted in reduced maintenance costs and prolonged equipment lifespan.

4.4 Customization: RAAH Group offered tailored choker solutions, considering the specific requirements and configurations of that company hose and piping systems. This customization provided optimal performance and efficiency.

5. Conclusion

RAAH Group’s innovative Hose and Piping Chokers provided a successful solution to that company’s challenges related to secure points and gauge usage. By implementing these chokers, that company achieved improved safety, efficient gauge monitoring, enhanced durability, and customized solutions for their unique requirements. With RAAH Group’s expertise and cutting-edge products, the partnership proved to be highly beneficial for their hose and piping systems, ensuring long-term reliability and productivity.