Client:

Manitowoc Cranes

Industry:

Manufacturing and Construction

Pain Points

Manitowoc Cranes identified significant safety risks during material handling activities in their factory. Workers were required to guide suspended loads manually, using their hands and fingers to assist in loading or moving components with a crane. This posed a serious risk for hand injuries, pinch points, and other accidents due to the unpredictable motion of the components.

The need for a safer, hands-off approach to guiding suspended loads became critical. The existing methods were both inefficient and unsafe, prompting Manitowoc to seek a solution that would mitigate these risks while maintaining operational efficiency.

RAAH Safety’s Solution

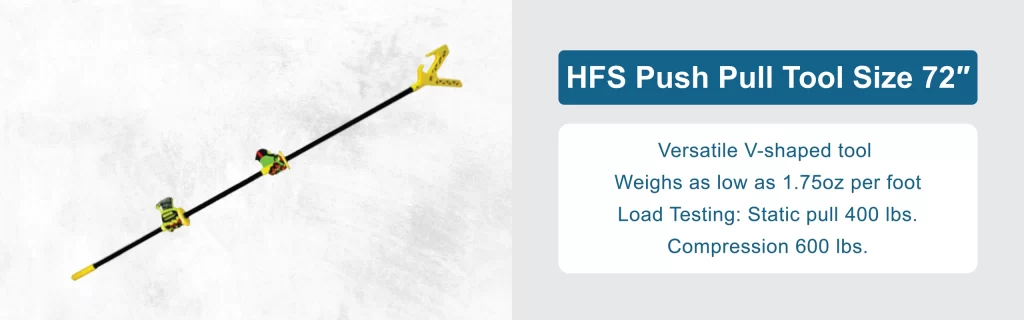

RAAH Safety, as an authorized distributor of HFS Push Pull Tools, proposed the HFS Push Pull Tool — a hands-free safety solution designed to guide suspended loads safely.

The HFS Push Pull Tool offered the following benefits:

- Hands-Free Operation: The tool eliminates the need for direct hand contact with suspended loads, reducing the risk of hand injuries and pinch points by maintaining a safe distance from the moving components.

- Enhanced Safety: It ensures workers can guide loads without being in close proximity to potentially hazardous parts, significantly improving overall safety.

- Durability and Efficiency: The tool, specifically designed for suspended loads, improves the efficiency of material handling while ensuring higher safety standards.

RAAH Safety suggested the 72” HFS Push Pull Tool as the ideal solution, considering the size and handling requirements of the components at Manitowoc.

Implementation

RAAH Safety worked closely with Manitowoc to understand their functional operations. After observing their material handling processes, RAAH Safety recommended the 72” HFS Push Pull Tool, which was identified as the right fit for their specific workstations. The implementation of the tool helped streamline the material handling processes and reduce the risk of worker injuries.

Outcome and Benefits

- Reduced Injury Risk: The introduction of the HFS Push Pull Tool significantly lowered the risk of hand and finger injuries, creating a safer work environment.

- Increased Worker Efficiency: With the elimination of manual handling for suspended loads, workers could focus on other tasks, boosting overall efficiency.

- Compliance with Safety Standards: The solution helped Manitowoc meet stringent safety standards, reinforcing a culture of safety and care in the workplace.

Client Feedback

The Manager of EHS at Manitowoc Cranes expressed satisfaction with the solution, emphasizing the critical importance of safety in their operations.

“We’re grateful for RAAH Safety’s innovative solution that directly addressed our safety concerns. The HFS Push Pull Tool has helped us reduce injuries, increase efficiency, and ensure that our team can work with peace of mind.”

— Manager – EHS, Manitowoc Cranes.

Conclusion

By closely collaborating with Manitowoc Cranes, RAAH Safety provided a tailored solution that greatly improved safety, efficiency, and worker protection. As the authorized distributor of HFS Push Pull Tools, RAAH Safety delivered an effective hands-free safety solution that aligned perfectly with Manitowoc’s safety objectives, contributing to a safer and more productive workplace.

Contact Information:

RAAH Safety

Head of Sales: Sushil

Email: sushil@raahgroup.com

Website: www.raahgroup.com | www.raahsafety.com