Morse 86 Series Drum Lifters

The Morse 86 series drum lifters were designed to create a mechanical design substituting the manual lifters or tag line lifting with secure mechanical replacement. Several industries deal with large drums that require lifting and transfer. Morse 86 is an innovative design that contributes to time efficiency, practicality and safety of the personnel. The security aspects of Morse 86 drum handling equipment are both based on decreasing the lifting accidents by a secure and locked transfer of large barrels.

Model 86

Made of carbon steel painted blue

It is used to lift the loaded drum with your crane connected to the hook. It helps to loading and unloading the drums for transport and other applications.

The strap to secure the drum not to slip and prevent the drum from falling.

Safety Conscious Lifters with Under-Drum Support

• Attach to crane, monorail or hoist

• Set drum on bottom support

• Secure chain around drum

• Lift steel, plastic or fiber drum

• Capacity: 1,000 Lb. (454 kg)

Lift and Transport Steel, Plastic or Fiber Drum:

• 22” to 23.5” (55.9 cm to 59.7 cm) diameter

• 23” to 38” (58.4 cm to 96.5 cm) tall

• Accepts Diameter Adaptors for smaller drum down to 14” (35.6 cm) diameter

Where is this drum lifter used?

• Docks and mezzanines

• Oil rigs and other marine applications

• Construction sites

Connect the drum and removing the drum from Morse drum 86:

Do not try remove the loaded drum with your bare hands which is unnecessary efforts everyone to avoid, we recommend to use the drum truck for easy handling as shown in the below picture.

We recommend to use the Model 160 4-Wheel Drum Truck for easy handling.

Attach the drum lifter to your hoist or crane to lift and move an upright drum. You may also attach it to your forklift with Morse model 284 Fork Hook.

Secure drum with web strap and ratchet positive grip mechanism around the drum. Drum is supported from below by a bar at the bottom. This ensures that your drum will be transported safely with no chance of sliding out. No tools are necessary.

Once loaded, the unit carries the drum without tilting it.

Each Model 86 and 86-SS is load tested at the factory at 125% of rated capacity as per American National Standard ASME B30.20. A load test certificate is shipped with each unit.

Utility

Any industry that handles transport, lifting or filling large barrels can benefit from morse 86, despite the container material- whether plastic, metal, and fiber drums up to nearly half a ton of weight attached to a forklift, a crane drum lifter or mechanical fixed mover in an industrial center. Here are some examples;

- Production and packaging of food industries

- Pharmaceuticals and chemical companies

- Offshore and onshore petroleum drilling platforms

- Paper and wood pulp productions

- Docks and mezzanines

- F&B industry

- Construction sites

Function

The Morse 86 Series Drum Lifters are designed to handle a weight of up to 1000 ILB which is equivalent to 450 metric kilograms. In addition to providing a convenient and direct solution to assist weight lifting that is rather difficult by labour force, the morse drum lifts are constructed to cater for accurate transport, decrease injuries such as crush points, burn points and chemical exposure. Furthermore, the rotatory center and its supportive bar provide facile morse drum handling, by presenting a firm grip around the drum.

From start up grabbing, lifting and transport, the drum handling morse takes care of the aspect. The first step is to attach the morse drum lifter to any house- both fixed mechanical arms or a forklift- and then fasten the belts, known as web straps, around the barrel in an upright movement, designed with secure hinges to avoid miscarried operations and mid-work incidents. This is an all-included edition and no additional tools or provisions are required.

100% manufactured in USA the vertical drum lifter keeps the barrel in an upright position throughout the transport, which may prove critical for specific categories of barrel contents.

Every Model 86 and 86-SS is tested at the factory at 125% of rated capacity before dispatching into the market and comes with a verification certificate that proves the barrel lifter offers impeccable load lifting capacity Designed for perfection, this drum lifting equipment boasts American Engineered perfection to deliver all the expectations.

The perfect hoist lifting attachments for this steel drum lifter is specialized for an array of transportation options, namely; morse drum truck, monorail movers, forklift drum lifters, as well as crane barrel lifter hoist supports. Separate drum lifting hooks are available for a variety of attachment surfaces.

Feature Specifications

These barrel lifting devices feature an under bar for increased support, a strap chain for ensuring the side barrel grip with a simple yet effective mechanism to keep the container from tilting or moving. Whether with a top lid for long duration transport or with no lid for production and mixing contents, the mechanism offers a flawless grip that ensures spill-free transportation of the barrel. Here are some specifications that help you to choose the perfect fit:

- Made of stainless steel, the corrosion free material in case of chemical exposure and extreme temperatures, in addition to offering easy washability without rust formation and efficiency in general maintenance.

- Applicable for a variety of barrel material including metal, plastic and fiber drum lifter

- Caters a range of barrel lifting sizes, in particular; 22” to 23.5” (55.9 cm to 59.7 cm) in diameter, 23” to 38” (58.4 cm to 96.5 cm) tall

- Comes with diameter adaptors to cater for smaller containers ranging from 14” (35.6 cm).

- Handles up to 1000 IBS or 450 Kg,

- Designed with a bottom bar and cinch strap for a lift up ratchet support cinching mechanism that offers external support and maneuvering of the container during lifting

- Each barrel is sold with a load test certificate for tilt-free and spill-free aesthetics

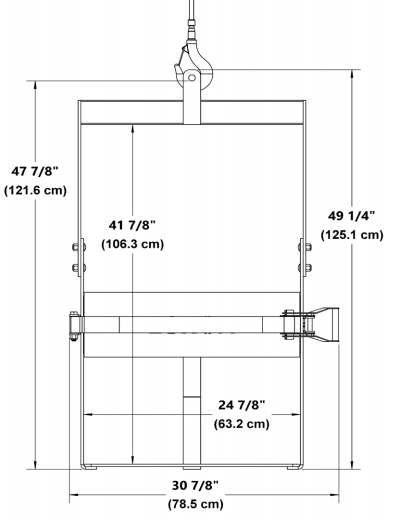

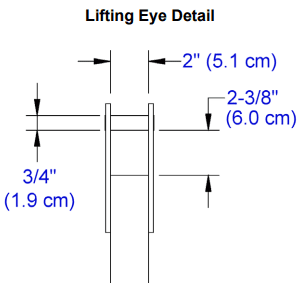

Drum Lifter Dimensions for Model 86

Is This Drum Lifting Device For You?

An evolutionary design among the mechanical drum and barrel lifting equipment, this drum grabber is dedicated to lifting and well-balance adjustment of lid-less or covered drums. Several factors in the construction efficiency of this device add to general safety of the personnel as well as decreasing the possible damages due to spillage of liquids or hazardous material.

As both a hands free safety device and drum transport assistant, numerous industries can benefit from this device while handling barrels such as processing, docks, refineries, etc. there are several drum lifters available in the market; if your job requires a 100 percent hands free and safe carriage of barrels indoors and outdoors, or needing absolutely tilt-free and spill free; this device is just for you.

Here at RAAH safety, we ensure to bring you safety tested products that match up to the description as well as your expectations of quality standards. If these specification do not match your requirements, check out our other drum lifter for sale, including; Morcinch Drum Handling System.