There are many types of Valves in the market available which are optimized with the help of CAE Software (called Sim Scale) that is a cloud based for the simulation of Valves ,that let us Optimize designs through CFD, test validate, heat transfer and Thermal Analysis.

There are few examples of Valve Design Simulation Projects are as follows:

1. Butterfly Valve Design Simulation

By applying a K-epsilon turbulence, the butterfly valve simulation was i

nstalled using the steady-state, incompressible flow simulation type. Following patches is being used in below boundary conditions:

For the Inlet patch- Velocity Inlet The Outlet-

Pressure Outlet is being used.

You may also check: Stuck in the hole! – Dropped Objects in the Rotary table shaft

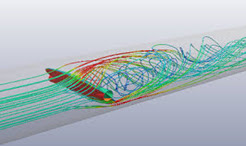

2. Water Flow Through a Gate Valve

• K-Omega SST model is type of turbulence model.

• In this model, 3D design is used for the visualization of distribution of velocity and pressure across the valves in streamlines.

3. Flow Analysis of a Double-Flanged Check Valve

In this project, simulation of the internal flow of water via a double-flanged check valve was demonstrated.

Following features were observed:

• Upgradation and utilization potential of the valve design.

• It gives an idea about the variation in the pressure distribution across the valve.

4. Ball Valve Flow Analysis

• In this project, a k- epsilon turbulence model was used for the simulation

• For internal flow, 1.5 million cell mesh with automatic hex-dominant mesh operation was developed.

5. Valve Under Internal Pressure

It is an examination of a pneumatic valve under internal pressure.

Following features are observed:

• It stresses on the structural response of the valve housing to the pressure present in the inlet part of the valve.

• It helps in detection of the malfunction in the design.

• It also gives vital information for its proper utilization.

6. Stress Analysis of a Pressure Relief Valve (PRV)

In thermal-hydraulic plants, to increase the security protocols the pressure relief valves are employed.

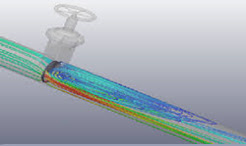

7. Optimization of a Globe Valve

Globe valve optimization project was employed to minimize the pressure loss of a globe vale.

To improve the proper functioning of the valve:

• Various changes in design were made.

• To improve the variation in the flow behavior, new flow channel was simulated

• Pressure loss of a globe valve. Taking into account the requirements channel was simulated.

8. Thermo-structural Analysis of a Steam Stop Valve

Steam stop valves are mainly employed in steam boiler plants to manipulate the flow of steam from the boiler to the mainstream pipe by using a movable plug.

9. Flow Simulation of a Regulator Valve

• In regulator valve simulation, a turbulent flow simulation of a regulator valve is manifested.

• Two meshes of different fineness was developed by using the automatic hex-dominant mesh operation.

10. Compressible Valve Fluid Flow Analysis

• To consider the turbulent effects of the flow, compressible fluid flow analysis and a k-omega SST turbulence model is availed.

• It took 1 hour on a 4- core machine to produce the valve simulation result.

RAAH specializes in sourcing for Valves that are of high quality and industry accepted. RAAH team of expert engineers’ source from across the globe, compare quotes and offer the best possible lead time and price to our customers. For more information log onto www.raahsafety.com or contact sales@raahsafety.com.

You may also check: The Inevitable Concern of Hand or Finger Injuries